Cart (0 Items)

Your cart is currently empty.

View ProductsIt looks like you are visiting from outside the EU. Switch to the US version to see local pricing in USD and local shipping.

Switch to US ($)

1570€

Your E.coli protein production

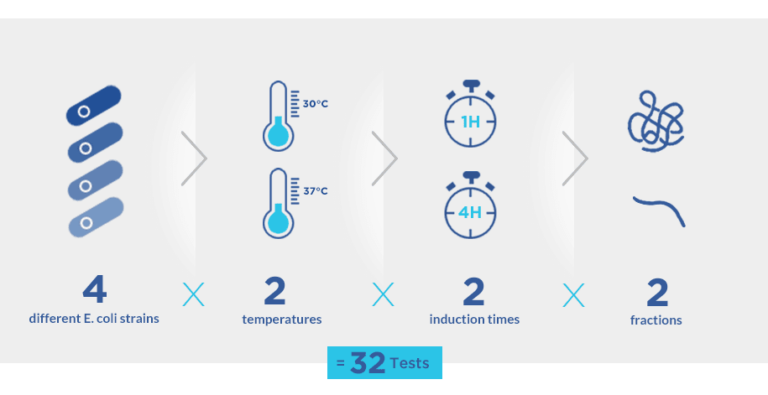

Optimize your chance to produce your recombinant protein efficiently! Our service of protein production in E. coli includes up to 32 protein expression tests in standard to guarantee that even the most difficult-to-express proteins have a high probability to be produced.

An ideal example of the insights you can expect from this type of report

This comprehensive report includes:

Our E. coli production package starts from 1570€.

Our protein expression packages include up to 32 expression conditions tests at that price.

Our E. coli protein production package includes a wide range of QC analysis.

As a gene synthesis expert, ProteoGenix can include gene synthesis and efficient codon optimization to its E. coli protein production.

We provide from milligram to gram protein expression in E. coli.

Our PhD account managers are at your disposal to guide you through our solution of protein expression in E. coli.

Recombinant protein production is highly technical and requires strong expertise as one production protocol cannot fit all product types. With more than 16 years of experience and 1500+ proteins expressed, ProteoGenix developed an in-house protocol including up to 32 expression conditions tests in its package of “Protein production in E. coli” to meet the best your requirements. The technical possibilities are almost infinite and such a long lasting experience is decisive.

You need to produce a protein in E. coli or want more information about our capacities of protein expression in E. coli? Our account manager is at your disposal to answer to your questions.

For difficult to express proteins we also have a dedicated high throughput screening service that allow to increase the probability to find the most optimal conditions. The more conditions are tested, the higher the probability to ensure optimal solubility, functionality, productivity…

All conditions are varied from codon optimizations, vectors with different promoters, protein sequences, purification tags down to the purification method itself, tag clivage conditions, refolding method and formulation. The advantage of protein expression in E. coli is the infinite range of solution and technology and ProteoGenix has a wide experience of all these technologies thanks to the large variety of project carried out until now.

Expression vector construction

E. coli strain transformation

Test of 32 protein expression conditions

Protein expression scale up and purification

QC analysis

| Step | Content | Timeline | Deliverables |

|---|---|---|---|

| Gene synthesis |

|

3 to 4 weeks |

|

| Small scale protein expression evaluation |

|

2 to 3 weeks |

|

| Protein production scale up |

|

2 to 3 weeks |

|

Options available:

One of our customers requested a recombinant protein production in E. coli. This project included also gene synthesis and subcloning in an expression vector (information included in the PDF report).

The aim of the protein expression tests is to determine the optimal conditions for protein expression by evaluation of:

More details about the protocol are provided in the complete PDF report.

Figure 1 : Expression tests of the target protein. Coomassie blue staining Reducing-PAGE analysis of NPE and DPE. MW. Molecular weight marker. Ø. Non-induced bacteria culture (negative control). Induction with IPTG 1mM.

The protein is expressed at high level in all strains tested, and is mainly localized in NPE (Figure 1). The optimal conditions for native expression are indicated in the complete PDF report.

A small-scale (200ml culture) purification test was performed in native conditions. Starting material: NPE prepared after optimal native expression. Details about the protein purification protocol are available in the complete PDF report.

Figure 2: Purification test of the target protein. Reducing-PAGE analysis with Coomassie blue staining A. Purification profile. B. Final sample QC (after buffer exchange) MW. Molecular weight marker. IN. Input. FT. Flow through. W1-W3. Wash steps. E1-E9. Eluted fractions.

The target protein was purified in native conditions (Figure 2). The yield and purity obtained are detailed in the Table 1.

| Strain No. | Purity* | Yield(mg/L)** | |

|---|---|---|---|

| XXX | No.1 | 90% | 146 |

Table 1: Production and purification yields Final buffer: TBS pH8.0. **Estimates based on the 200ml-culture tests. *Based on the 2µg loadings in Figures 2B (green arrows)

“ ProteoGenix assisted me with the generation of a peptide and a protein. They were very helpful throughout the entire process, and provided invaluable information and recommendations based on their expertise. Based on this experience, I look forward to future collaborations with ProteoGenix ”

“ ProteoGenix is for us a reliable partner for the production of recombinant proteins in E.coli and always provided an excellent service, with regular updates, quick response to our queries and delivery of product in high quality. We appreciate the collaborative attitude and professionalism of ProteoGenix.”

E. coli is a well-characterized organism for protein production and was the first host expressing an approved therapeutic recombinant protein.

Until the middle of the 90’s, E. coli was considered as the best choice for biopharmaceutical production due to several advantages such as:

These advantages make E. coli the best choice if you are looking for a fast and cost effective protein expression solution.

However, protein production in E. coli may not be the most relevant solution for the expression of complex protein structures including post-translational modifications or biotherapeutic productions due to high levels of endotoxin (which can be removed thanks to our endotoxin removal service).

To get more information about our protein production in E.coli platform, please feel free to contact our dedicated account manager.

Inclusion bodies are often considered as a bottleneck in recombinant protein production but they are often related to high protein expression levels. Several approaches have been developed to limit their formation but only irregular results have been obtained because protein production is product dependent. It is for instance possible to produce at low temperature using specific strains. However, inclusion bodies can present several advantages:

Thus, many microbiologists developed protein refolding protocols allowing the exploitation of these inclusion bodies as a source of recombinant proteins.

At ProteoGenix, we developed a unique protein refolding platform tailored to best exploit recombinant protein expression and meet your requirements. To get more information about it, please feel free to contact our dedicated account managers.