-

Customers success stories

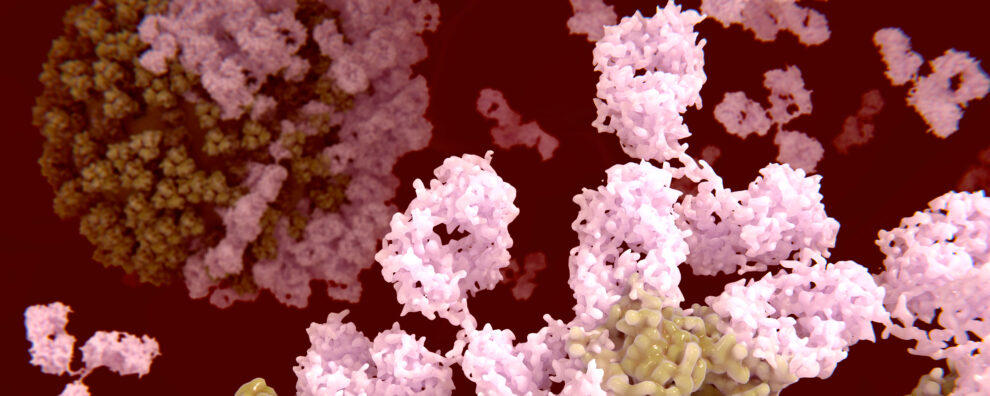

Customers success storiesThe Path of Creating an Innovative IL-17A Antibody for Autoimmune Disorders

At ProteoGenix, we are devoted to promoting innovative research and offering superior solutions that assist our clients in reaching their scientific objectives. Our client at the University of Naples and…

-

CAR-T cell therapy

From the first to the fifth generation of CAR-T cells

Read more -

CAR-T cell therapy

The structure of CAR-T cells

Read more -

Antibody-drug conjugates

Robust methods for the detailed analysis of drug-to-antibody ratio (DAR) and drug load distribution

Read more -

Antibody-drug conjugates

ADC payloads

Read more -

Antibody-drug conjugates

How to choose the best linker for an ADC? Cleavable vs. non-cleavable

Read more

-

Customers success stories

The Path of Creating an Innovative IL-17A Antibody for Autoimmune Disorders

Read more -

Antibody production

Polyclonal vs. Monoclonal antibodies: How to choose the best option for your project?

Read more -

Antibody production

How to choose the best antibody generation technique for your project?

Read more -

Antibody production

The best CHO expression system kits on the market

Read more -

Antibody production

A guide on how to easily transition to a new antibody expression system kit

Read more

-

Antibody production

“The COVID-19 pandemic is helping us bridge the divide between virologists and immunologists”

Read more -

Antibody production

Reinventing IgY biotherapeutics

Read more -

Antibody production

How the environment shapes immune system development during pregnancy

Read more -

Antibody production

“Cell-based phage display is helping us isolate more biologically relevant antibodies”

Read more -

Antibody production

“Researchers are not leveraging the speed and resolution of flow cytometry for clinical evaluation”

Read more